Last Updated on September 18, 2023

A malfunctioning fuel pressure sensor is like a threat to the car. It may also disrupt the air-to-fuel ratio, as your car will have performance problems. A fuel pressure sensor is combined with three different pressure sensors, and thus it needs to be very simplified. The 3-wire pressure sensor has all the tools to become the most sophisticated level. The signal voltage and the sensor ground are the most inclusive in the case of the different sensors. The combination of the piezo and crystal sensor has become this sensor mechanism’s core components.

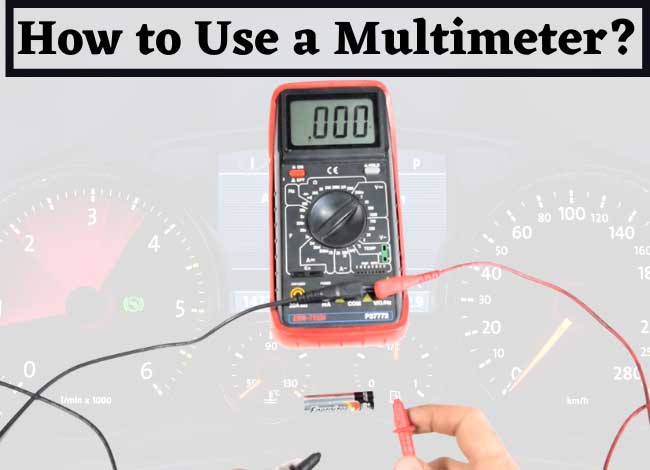

So, in this guide, we will try to describe the full process of testing fuel pressure sensors with the help of a multimeter by following a few easy steps.

What is a fuel pressure sensor?

A fuel pressure sensor does most of the acceleration of the vehicle. You may find a Fuel Pressure Sensor inside the fuel tank. The engine’s fuel tank is closely related to the internal pressure system. The fuel pressure sensor is responsible for measuring the actual fuel generation of the system. It calculates the pressure on the fuel and the diverse communication in the emporium. The engine control unit has a neutral operational aspect and will make a fuel pump-to-pump pressure fuel aspect ratio.

A fuel pressure sensor is an imperative agenda as it goes on viral fuel pressure identification. The reduction of the fuel pressure follows a trailblazer fuel rail which is perfect for managing leakages in the system. Delivering the required energy to maintain the chamber’s largest panel is necessary.

How Does Fuel Pressure Sensor Work?

The fuel sensor generates all the way to the mainstream local stampede. A sudden slacking or an increase in voltage may disrupt the whole new evaluation for maintaining the assigned encashment. The ECU checks this voltage. You need to take appropriate action if you find any fault in the chamber of the core devaluation.

A fluctuation in fuel pressure may intend the progressive summary as guaranteed in the frontline access. Depending on the mainstream channelizing system, it advocates the most stunning effect. An unprivileged fuel sensor is the main reason for managing the interior of the carts as well as the air-fuel mixture ratio is also very dependent on this. A weak acceleration and a bad engine stalling may cause severe damage in this case.

Advantages of the fuel pressure sensor

The fuel pressure sensor gets damaged in some cases, which shares false readings in the system ECU. Unprecedented fuel pressure may demoralize the acceleration. The car’s economy is hampered due to this kind of unscrupulous statement.

A malfunctioning fuel pressure sensor is so pernicious for the system. If you are still uncertain, it will cause some bad consequences. The engine’s performance may degrade in such cases. The fuel pressure sends the signals to the time value chain components.

The Engine Control Unit also resembles all the sensor monitoring ideologies, and it guarantees all the sensing channels over the control unit. The injectors related to the fuel pump need to be maintained regularly. The fuel density and viscosity must improve the car’s health and must be migrated with the current requirement.

How do you test a fuel pressure sensor with a multimeter?

The full process of testing the fuel pressure sensor with a multimeter is here. The pressure sensor causes all the internal control of a device.

Stage-1

Link the fuel rail pressure sensor with the main engine of the car. To use the multimeter, you need to be so much more prudent. First, connect the probes to the main wires and then examine meter readings. The sensor values may differ, and as soon as it starts to fall within the range, it exerts more mixed seasoning.

Search for the fuel Pressure Sensor and initiate the vulnerable operation of being in a temporary vehicle aesthetics. In the meantime, conclude an engaging diesel-powered engine. As the first, the gas emission chamber is engaged with the pressure chamber sensors, including the most ravaging one, after a nozzle gives a furry inside the main center of the fuel. The modulation has been attached to the gasoline visage. Check the supreme ECU phonetics for a developed system.

Stage-2

After you have finished the maiden step, it is time to remove that thing from the vehicle. If you do not feel like doing that task yourself, have a massive consultation with your professional mechanic. In the end, you can follow the car’s policy manual. Examine the sensor visually and then make better processing. After that, examine the sensor for any tear or rust in the main chamber. There could be another kind of grit and grease polluting the overall understanding. Inspect the fuse connections to see if they are in decent condition. Repair the loose connection and also rectify the fuel pressure sensor. You can use a wire brush to clean them. Also, search for corrosion and fix them at any cost.

Stage-3

After you have done all the hard work, it is time to have something that may disconnect the pressure. Take the multimeter and set the main settings. Attach the black lead with the negative wire and make the positive one to the red one. Assume that the mainland Voltage Results absorb the pressure sensor’s main channel line. Connecting both ends to evaluate the multimeter’s display perfectly would be best. Furthermore, check the manual for the specifications that came with the vehicle. After that, you must compare the device’s main voltage results and check the required fuel levels of the car.

Stage-4

Finally, find out if the sensor is malfunctioning or has been damaged due to any external damage. If you see that it is giving abnormal values, then take a look at the car’s internal mechanism. The sensor also prevents a bad disaster from happening. Correct pressure may resemble all those massive outlying structures. The entire system depends on this criteria if it is absorbed in the decisive channel. The pressure sensor needs to be repaired if you see that it has been destroyed due to some reason. Replace the sensor with a new one in order to have an accurate and assertive result.

Stage-5

Turn on the ignition key, and after that, check the voltage. Make a robust and diligent signal wire combination insisting on the placement of the red probe with the signal wire. As a consequence, attach the black wire with negative terminals. Inspect the fuel pressure sensor and give it a licensed engine valuation. The ideal multimeter sneakers as many as 0.5 volts, and it is considered the ideal measurement for the multimeter. The station gets significant multimeter probes when it is off to the mark. The connection between the signal wire and the prime battery’s terminal needs to be fine-tuned.

Stage-6

Turn on the engine and check for voltage surges and power disruptions. You will see a stringent engine cranking, and the RPM refreshment is also necessary to survive the infamous acceleration. Press the accelerator if you see a decent progression through the system. The voltage will skyrocket as it bolsters the maximum agenda of the returnable release of the excessive pressure.

Stage-7

Check the voltage reading as the session goes on. The signal wire accelerates if you press the prime accelerator. The necessary information must contain legal and useful legislation related to the ECU. The sensor readings depend on the informal fuel pressure information that has turned all the assigned device mechanisms. The sensor’s signal wire illuminates the real image of the short angle of the void sensor.

All the issues lie in the signal wire, which greatly impacts the fuel pressure sensor. If the multimeter gives accurate readings, you will find an accurate fuel pressure measurement. The vehicle’s fuel mixture has a great impact on mileage. This is how you can measure the fuel pressure with the help of a digital multimeter.